Turner is a North America-based, international construction services company and is a leading builder in diverse market segments.

GET TO KNOW US

Our people bring their technical knowledge, experience, and resourcefulness to the delivery of our construction services. Our expertise and value-added offerings support our clients throughout the lifespan of the construction process.

Stay up to date with the latest news and insights from Turner. Learn from our industry experts sharing innovation, market insight and thought leadership.

Browse Insights

An awarding and fulfilling career awaits you at Turner! Join our team and build some of the most exciting and innovative projects around the world.

Explore careers at Turner

Turner is a North America-based, international construction services company and is a leading builder in diverse market segments.

Get to know us

Our people bring their technical knowledge, experience, and resourcefulness to the delivery of our construction services. Our expertise and value-added offerings support our clients throughout the lifespan of the construction process.

As the largest general contractor in the country, Turner is a leader in all major market segments, including healthcare, education, commercial, sports, aviation, pharmaceutical, retail and green building.

See Our Portfolio

Stay up to date with the latest news and insights from Turner. Learn from our industry experts sharing innovation, market insight and thought leadership.

Browse Insights

An awarding and fulfilling career awaits you at Turner! Join our team and build some of the most exciting and innovative projects around the world.

Explore careers at Turner

Headquarters

Turner Construction Company

66 Hudson Boulevard East

New York, NY 10001

(212) 229-6000 turner@tcco.comEthics & Compliance Hotline

Report issues 24 hours a day, 7 days a week to Turner’s Confidential Reporting System

(888) 738-1924 https://turnerconstruction.ethicspoint.comSend

Subcontractors

Before reaching out, please review our prequalification requirements.

Become a Subcontractor

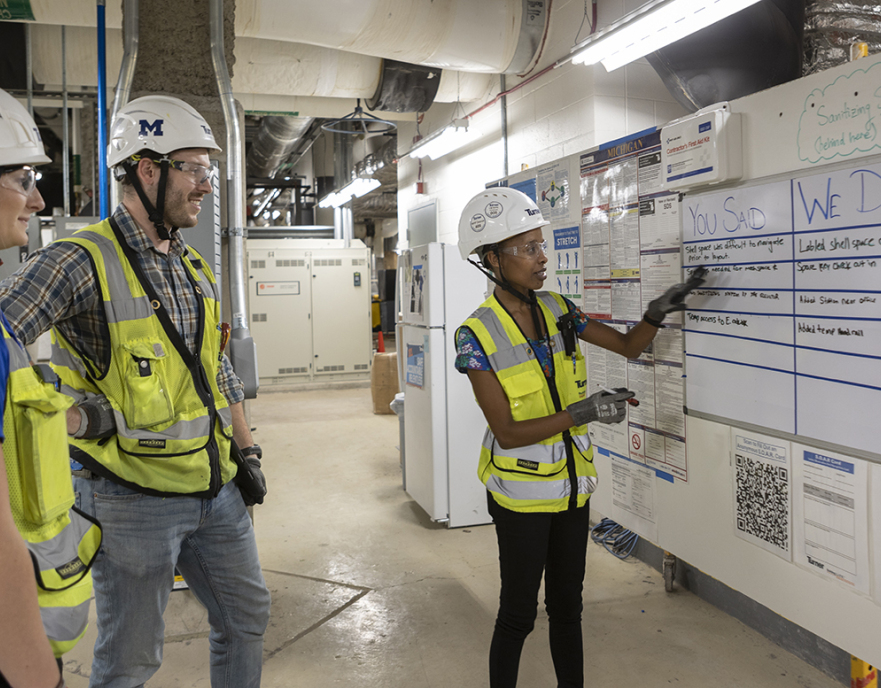

Lean is a philosophy that emphasizes the elimination of waste to create a smoothly flowing production process that produces only what is needed, when it is needed, and in the quantity needed.

Our Lean Construction practices emphasize the elimination of unnecessary steps and resources in order to enhance project schedules, quality, and customer satisfaction.

Our Lean Management practices include using data and metrics to guide decision-making, empowering our entire workforce to identify and solve problems, and implementing a culture of continuous improvement.

Our leadership plays a significant role in promoting lean construction practices throughout our global office network. By establishing an enterprise-wide strategy and through their support of local offices with the necessary resources, the Lean Construction group drives positive change throughout Turner.

Senior Vice President

Lean construction improves efficiency, reduces waste, and increases productivity through streamlined processes, eliminating unnecessary steps, and effective resource utilization. Tools like value stream mapping, kanban, and 5S reduce costs and improve project and operational quality.

This is a process where work is only started when it is needed, rather than on a predetermined schedule. This helps to reduce unnecessary work and improve overall efficiency.

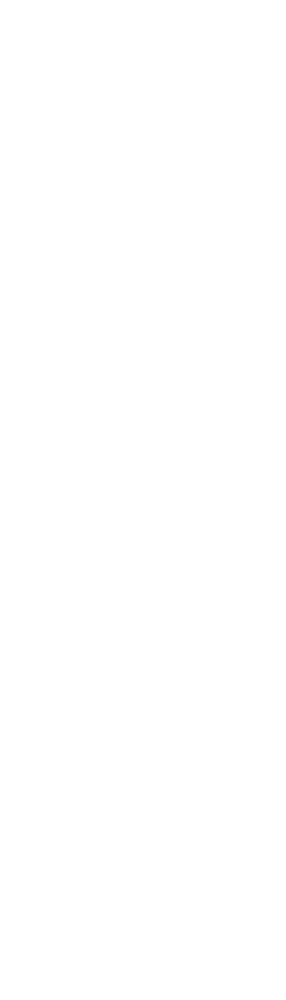

Kanban is a visual system for managing workflow, where work is represented by cards or tokens. This helps to make the workflow more visible and allows for real-time adjustments to be made.

This is a system that uses pull planning and Kanban to manage workflow and improve collaboration between different teams.

This is a system that focuses on maintaining and improving equipment and machinery to reduce downtime and improve efficiency.

Turner provided construction management services on this new world-class library for the Town of New Canaan which serves as the Crown Jewel of the Town. The Town worked for over 10 years to develop a transformational space that amplifies the library experience for families—connecting people, perspectives, and information to help build a more engaged, inclusive, and empathetic world.

Learn more about this project, visit showcase